Technical Quality

Technical Quality

Quality is our primary requirement. To ensure the safety of the products used by consumers, we carefully monitor the quality of the products by "Manual inspection", "process system" as well as “machinery and equipment” in the process of research and development of lenses. From the process of feeding, manufacturing to finished products and sterilization, the company has undergone strict computer quality control, and cooperates with qualified QC to conduct inspections through MIL-STD 105E international quality inspection standards. After rigorous quality inspection, including lens appearance inspection, accelerated aging test, dissolution test, physical and chemical property test, biocompatibility and toxicity test, microbial test, etc., and human clinical test. Besides, we cooperate with domestic and overseas inspection agencies, laboratories and hospitals. Not to mention Smart Performer CO., LTD has also obtained a multi-national patent certificate.

Technical Process

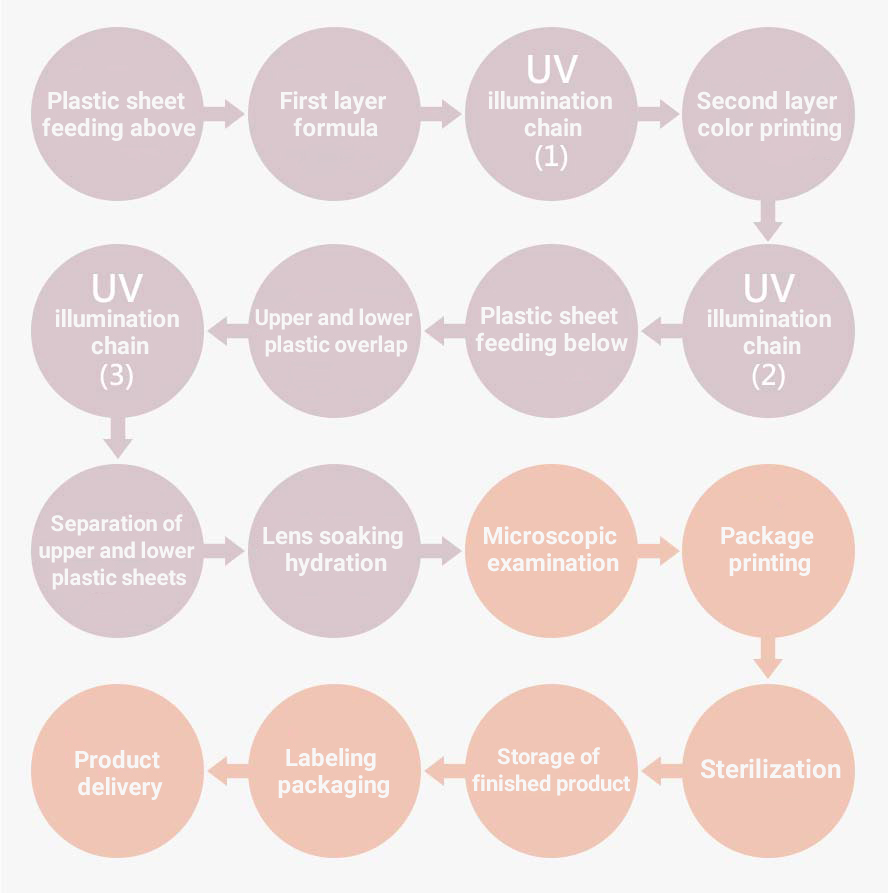

Our company mainly uses wet cast molding technology, and then further innovate and develop gradual coating to manufacture contact lenses. Putting liquid polymer into the mold in order, the pigment and pattern in the middle layer are coated between the upper and lower lenses through UV reaction. After the process of demolding, hydration, surface inspection, high temperature, high-pressure moist sterilization and packaging, the product is ready for shipment.

R&D / Material Design

Our company has unique production technology called wet cast molding. The superiorities of this technique includes quality stability, fast molding speed of lenses, and suitability for mass production. In the design stage, the contact lens focuses on the design of the center part of the mold, for it is critically related to the structure, quality, application and specifications of the lens. In 2013, we purchased CNC optical equipment to provide a strong product design flexibility by self-processing and manufacturing various mold cores, effectively reduce costs under the condition of small quantity but greater in variety. To effectively reduce costs, production efficiency and yield rate must be able to be controlled and improved immediately. Our R&D department has a professional team to control the relevant parameters of the process, and make fast adjustment according to the targets of the company.

Research on lens materials is also one of the focuses of us. For the improvement of transparency, permeability and moisture retention of existing contact lens products, the analysis and research of related raw materials are extremely important.

In the future, we will continue to develop color contact lenses with various functions. Such as the addition of long-lasting moisturizing formula to make consumers wearing contact lenses more comfortably; anti-UV lenses to reduce the damage of ultraviolet rays on the cornea, lens and retina, or add a zoom function to make the ciliary muscles adjust to see things more easily.